INDUCTION LAMPS & BALLASTS

INDUCTION LIGHTING

By using electromagnetic fields, induction lamps are able to produce more visible light than traditional lighting sources while reducing power consumption by up to 50%. Also, because there is no filaments or electrodes to burn out, induction lamps last about 5 times longer than High Pressure Sodium and Metal Halide bulbs.

With induction lighting you get superior lifetimes of 100,000 hours, a higher CRI (better quality of light), superior energy efficiency by achieving more visible lumens per watt (less power consumed, and less lumen depreciation over long periods of time.

Induction lighting offers instant-ON, instant re-strike, flicker-free and glare-free.

COMPARISON OF INDUCTION TO HID

INDUCTION OR HID - WHICH IS RIGHT FOR YOU

We are often asked which lighting technology is the best to use. Each lighting type has its own set of distinct qualities and shortcomings. This is not an easy comparison. It is virtually impossible to get an “apples to apples” comparison, but taken in the most simplistic comparison of lumens per watt per dollar cost we may have front runner.

A comparison of HID technology to Induction technology will show a distinct energy advantage using Induction fixtures over traditional HID fixtures. Using a general rule-of-thumb that an Induction Light uses 40%-60% of the wattage of an HID, a 200 watt Induction Light will provide the equivalent perceived illuminance output of a 400-watt Metal Halide or High Pressure Sodium lamp and is the most cost effective choice.

Construction of parking lot lighting typically has used 400-watt Metal Halide fixtures to provide adequate illumination measurements. To get the same visual brightness a 200-watt Induction lamp could be used and the energy savings would exceed 50%. Because the difference in lumen maintenance (lumen output over time) is significant between Induction Lighting and Metal Halide lamps, it must be considered along with the CRI and color temperature to make accurate comparisons as to equivalency of lighting types.

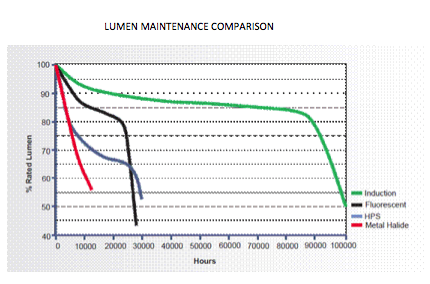

LUMEN MAINTENANCE

One major factor of a lamp is lumen maintenance, or how much light is lost over the life of the bulb. While initial lumens define the design parameters, the mean or average lumen output reflects the more real-world performance of the lamp.

The average rated life of a 400-watt Metal Halide bulb is 17,500 hours. At one year of operation, or less than 50% of its service life, Metal Halide’s light output and efficacy experience severe degradation. A 400-watt Metal Halide may produce 34,000 initial lumens, but only 24,000 average lumens at only about 9,000 hour life. Said another way, a Metal Halide bulb will lose more that 30% of its lumen output in less than half its life.

So, a Metal Halide’s “average” performance over time is much lower than its initial ratings by a significant amount. Induction lamps on the other hand (100,000-hour life), retain 90% output after 20,000 hours (that’s already more than the rated hours on Metal Halides) and still puts out 80% after 60,000 hours. You would have to replace at least 6 metal halide bulbs by then and the last bulb would be running at 50% output.

LUMEN PERCEPTION

In lighting design there are two distinct kinds of lumen output produced by lamps. The first is called Photopic or Design Lumens, which represent the relative sensitivity of the eye under intense lighting such as daytime, full outdoor sun conditions. Photopic lumen output is registered by the cones in the human eye and is measured in Lumen, Lux and Foot Candles.

The second type of lumens are called Scotopic, which represents the sensitivity of the eye under typical Interior or night lighting conditions and cannot be measured directly with a standard light meter. Scotopic lumen output is registered by the rods of the human eye and also controls pupil size directly effecting visual acuity for given task levels.

Traditional light measuring meters have been calibrated for use in the photo industry (thus the term Photopic meter). Most lighting designs use Photopic readings as design lumens to build and recommend lighting solutions. Unfortunately, Photopic meters can be deceptive in that what is bright to the machine is not always what is bright to the human eye, which measures light as Scotopic lumens. An example of this is the yellow light that is emitted from HPS which has an extremely high design lumen reading, but low pupil, or Scotopic readings.

Different light sources

Design Lumen readings can be compared when read by a standard light meter and measured in Conventional Photopic Lumen values. For lighting design that wishes to maximize energy efficiencies by specifying light sources with both high Scotopic and Photopic lumens, a Correction Factor (S&P Ratio) must be applied to the Photopic Lumen per Watt readings. When applying this factor you will notice drastically different usable light outputs as measured in Pupil Lumens per Watt. Higher Pupil Lumens per Watt will significantly reduce the amount of energy necessary to satisfy the task lighting requirements. Induction Lights use an S/P Ratio of 1.96:1.

A 200 watt Induction Light has 21,000 Initial Design Lumens, but has over 37,000 Initial Pupil lumens while a 400 watt Metal Halide has 34,000 Initial Design Lumens, and 35,800 Initial Pupil lumens. That is one factor why the human eye can perceive a brighter light when the source produces lesser Design Lumens. The table below summarizes this data.

| Lamp | Wattage | Initial Lumens | Lumen Depreciation | Mean Lumens | S/P Ratio | Effective Scotopic Lumens |

|---|---|---|---|---|---|---|

| Metal Halide | 175 | 17500 | 30% | 12250 | 1.49 | 18250 |

| Metal Halide | 200 | 21000 | 30% | 14700 | 1.49 | 21900 |

| Induction | 150 | 15500 | 10% | 13950 | 1.96 | 27350 |

| Metal Halide | 400 | 34000 | 30% | 24000 | 1.49 | 35760 |

| Induction | 200 | 21000 | 10% | 18900 | 1.96 | 37044 |

QUALITY OF LIGHT

Color Rendering Index

The CRI is a measure of a lamps ability to render an object’s color on a scale of 0-100, the higher the CRI, the more true to life the colors appear as they would in natural daylight. The CRI of and induction light is 85-90 while the CRI of a metal Halide is 65; therefore, the human eye perceives objects observed with Induction Light to appear truer to their appearance.

Color Temperature

The actual color of a light source is measured in degrees Kelvin (K). An Induction Light is typically 5000K, a full spectrum, white light, while the Metal Halide is 4000K a little on the yellow side. Pupil size plays an important role in vision in that smaller pupils results in better acuity, improves depth of field and allows less accommodative response of the eye. Raising light levels will reduce the size of the pupil but this can add glare and waste energy. The higher the color temperature, the more the lighting is scotopically enhanced. This higher color temperature causes more of the rods to be activated laying claim that an area may appear to be brighter even though a traditional photopically designed light meter might indicate otherwise.

MAINTENANCE SAVINGS

It is estimated that the cost to perform one (1) re-lamping is about $40.00 in maintenance technician labor time and a new bulb. If the Metal Halide bulb has to be replaced six (6) times for every one (1) Induction Light, then the total life-time maintenance cost is $240.00 per fixture. A significant benefit from Induction Lighting is the time saved for maintenance personnel, which allows them to do the major maintenance work they are paid to do – not to change light bulbs.

CONCLUSION

Combining the Lumen Depreciation, Lumen Perception and the Quality of Light (high CRI and Color Temperature) characteristics demonstrates why an Induction Light can produce the equivalent amount of perceived light output (pupil lumens) at 40-60% of the energy required from a Metal Halide bulb.

The 100,000-hour life of the Induction Light contributes significant savings in energy costs and maintenance time and is extremely cost effective making the total payback very attractive.

A 400-watt Metal Halide can be replaced one-for-one with 200-watt Induction Light and achieve comparable foot candle levels with half the energy.

Induction Lights are Instant-On and Instant Re-Strike. They have no flickering, strobing and produce no electromagnetic interference. The electronic drivers eliminate the annoying characteristics of magnetic ballasts ‘hum’ found in HID systems and can be used with conventional dimming systems to further reduce lighting energy demand.

Bottom line……… Southern Lighting believes that when you compare the lumens/watt/dollar cost of HID, Induction and LED lighting products as of right now, Induction is the most cost-effective lighting source to use. With the advancements in lighting technology moving at, no pun intended, light speed, that is our opinion today. In six months we may have another product to lead you to. Did I mention Plasma?